MJM Systems | STOCKT

What is STOCKT?

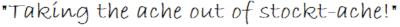

STOCKT is a super-efficient tool for school stocktake, accepting the standard SAP bar-code stickers as input. It's called STOCKT because it takes the ache out of stockt-ache!

It has been custom-built from scratch to empower school staff to easily manage their own stocktake, without the need for any outsiders to enter the site. It does not lock schools into repeat usage because it uses the standard SAP bar-code stickers, and all data remains accessible and readable by school staff.

I have closely examined the equipment stocktake system used in NSW Department of Education schools, and have ensured that STOCKT addresses the issues that arise for DoE school staff during their equipment/asset stocktake process.

Benefits and Features

STOCKT is an efficient bridge across the tedious, time-consuming and inefficient sections of the stocktake process in schools (data compilation, comparing and editing data, exporting the new equipment list). The end result is an error-free TXT file ready for upload to SAP. In addition, it creates all necessary reports both during and after stocktake.

It doesn't re-invent or duplicate what SAP itself does. The initial downloading of data (the XLS file) from SAP (prior to stocktake), and the final uploading of output data (the TXT file) back to SAP (after stocktake) are still handled by school staff.

STOCKT is largely touch-screen driven. It doesn't re-invent or duplicate what SAP itself does. School staff still oversee the initial download of the equipment list from SAP (in TXT or XLS file), and the final uploading of output data (the TXT file) back to SAP after stocktake. Here’s a quick overview of its function:

- Computer volume adjusted to 80% on opening, ready to give audible alerts.

- SAP's equipment/asset list data (from the downloaded XLS file) is imported.

- All data is kept within STOCKT (no external storage needed).

- Users can enter their name, so that the items they scan are tagged as being found by them.

- Statistics are displayed (date of download, date of import, number of items, etc).

- Current room number is easily selected.

- Demountable building numbers can be easily added for quick selection.

- Bar-codes are scanned in.

- Manual entry of data is still possible if so desired.

- Item description, serial number and equipment number appears on each scan.

- Audible and visual alerts are given for a range of non-normal situations.

- Alerts are very easily managed via your laptop's touch screen.

- Records the date/time of each scan, down to the second.

- Remaining items to be sighted/scanned are counted down as stocktake proceeds.

- Most of the interface actions are touch-screen friendly.

- ROOM CHANGES ARE EXTREMELY EASY TO DO 'ON THE GO'.

- Clear PDF progress reports are easily generated:

- All items found by a particular user so far, so they can sign off;

- Their portion of stocktake;

- All sighted items only;

- All Unsighted items only (these reports are great for tracking down the remaining items, and form an excellent audit record);

- Attachments 1, 2 and 3 for inclusion with our 'School Stocktake Certificate';

- All pre and post stocktake data for archiving and auditing;

- Items sorted by 'Equipment Number', 'Room Number', User who sighted the item, 'Loan To' data, 'Last Sight Year';

- Etc.

- Handover to another staff member during stocktake is easy due to these progress reports.

- Backtracking after interruptions is easy due to display of the last scanned item.

- One-click generation of tab-delimited TXT output file, ready for upload to SAP.

- All stocktake data is retained in the tool and accessible for audit.

- More audit information is available than previously.

- Auto-save on closing, to preserve data.

- Very easy to use.

- The XLS file originally downloaded from SAP is left unchanged.

Try it for yourself!

A 'Walk-Through Evaluation and Self-Training' package has been created so that school staff can evaluate the system easily in their own time. It consists of STOCKT itself and the accompanying 'Walk-Through Evaluation and Self-Training Guide' (a PDF document).

STOCKT comes pre-loaded with a small equipment list of 32 imaginary items that match the explanations in the accompanying training guide. The PDF guide MUST be printed in order to run through the scanning/training process properly. Your stocktake staff can follow the guide's small, imaginary stocktake at their leisure, and become familiar with the STOCKT system while evaluating its suitability. In particular, please note the progress report creation section. It's very powerful!

Competitive Pricing

- STOCKT pricing is extremely competitive.

- Existing school resources are utilised and leveraged.

- Standard SAP barcode stickers are used, so you are not locked in.

- Twelve-month licence structure gives you further freedom and control.

- Fully assess STOCK without any contact or obligation.

...and this online free quotation page adds further transparency:

Download the Application Form

To get started with STOCKT please feel free to download the below application form and follow the instructions within.

Applying bar-code stickers

Prior to the creation of bar-code scanning tools like STOCKT, there was no incentive to apply bar-code stickers. However, now there is! To use a system like this, it's important that your SAP bar-code stickers have been applied to all (or nearly all) of your equipment items.

It's sometimes difficult to figure out which sticker matches which particular item. This is one of the most tedious steps in preparing for bar-code scanning.

Here's a process that utilises the Find function (Ctrl + F) that's built into Adobe© Acrobat© PDF Reader. This process would be best used on a laptop while walking through the school finding equipment, carrying the printed sticker sheets with you. Please check these steps beforehand and see if it makes sense to you:

- When creating the bar-code stickers in SAP, save the PDF file that SAP presents to you (you'll use it again later).

- From that PDF, print all of the sticker sheets in one go, onto the correct Avery sticker sheet blanks (L7060 recommended).

- On the Fuji Xerox printers that are common in DoE schools, I've found that the bar-codes are positioned correctly on the stickers if I use the 'Fit' setting in the print dialogue. However, test this for yourself by first printing only one test page.

- DEFINITELY keep all the Avery sheets together in the same order that they came out of the printer. That's the same order as they're displayed in the PDF.

- Immediately mark the Avery sheets with the same page numbers that are shown on them when the PDF is opened in Adobe© Acrobat© PDF Reader (page 1, 2, 3, 4, etc). This is important! Maybe use a texta pen.

- For a particular equipment item, first find the serial number on the equipment.

- Open the PDF file in Adobe© Acrobat© PDF Reader so that you can see the bar-code stickers in the PDF on the laptop screen.

- In Adobe© Acrobat© PDF Reader, press Ctrl + F on your keyboard to open the 'Find' function.

- Enter the serial number (or part thereof) into the 'Find' function window, and press 'Enter'.

- Adobe© Acrobat© PDF Reader will search through the PDF, and display what it found.

- In Adobe© Acrobat© PDF Reader, note the page number of the result, AND the position on the page where that particular sticker is located.

- Go to the appropriate sheet/page in your pile of Avery sticker sheets (you'll have them marked as page 1, 2, 3, 4, etc).

- On that sheet/page, find the sticker that's in the same relative position on the page as what you saw in Adobe© Acrobat© PDF Reader.

- Check that you have the same serial number (it's displayed on SAP's bar-code stickers).

- That's the sticker that you peel off and apply to the equipment item.

Barcode Scanners

If you're in the market for a high quality bar-code scanner I would highly recommend the Zebra © DS2200 series scanners. I have found the DS2208 scanner to be a very high quality and reliable scanner with 1D and 2D capability. This scanner comes highly recommended.

Please feel free to check out their site at the link below:

DS2200 Series Imagers | Zebra (External Link)

DS2200 Series Imagers | Zebra (External Link)

Here's a link to a Sydney based supplier of this scanner:

Zebra DS2208 2D-SR Scanner Kit USB Stand Black (External Link)

Zebra DS2208 2D-SR Scanner Kit USB Stand Black (External Link)

Please note that MJM Systems is not affiliated in any way with Zebra © Technologies Corp. or Only POS (a Brand of Swift Computers Pty Ltd.).

STOCKT Quote Page

STOCKT Quote Page